Lecture 1b: DFM For Dummies

📝 Abstract

DFM optimizes the ease of manufacturing and production costs of ICs while meeting performance, power, and reliability requirements. As ICs become increasingly miniaturized and complex, the manufacturing process is more sensitive to variations and defects. Chip quality and functionality may suffer if not addressed through Design for Manufacturing (DFM). DFM can be applied to multiple aspects of IC design, including circuit design, logic design, layout design, verification, and testing, to mitigate manufacturing issues.The lecture provides general guidelines for DFM. Best practices for DFM in IC layout design can reduce design iterations, improve collaboration with foundries, enhance product performance and functionality, and achieve faster time to market. Applying DFM techniques in the physical design stage can greatly benefit IC development. Lowering production costs. The lecture covers the challenges of Design for Manufacturability (DFM) as well as its market share. The lecture includes DFM analysis and verification, enhancement, optimization, and the algorithms used to solve DFM problems. The lecture includes DFM analysis and verification, enhancement, optimization, and the algorithms used to solve DFM problems. The course structure focuses on the problems that arise from DFM and presents them in mathematical forms.

Faster, smaller & smarter

Silicon Gold Rush?

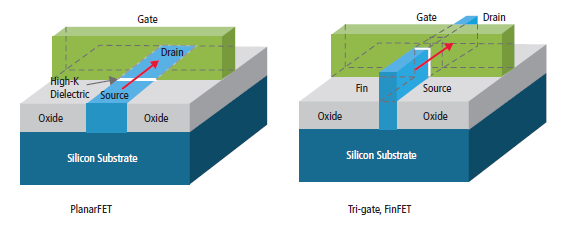

Current Transistors

- High-K dielectrics, Metal Gate (HKMG)

- "3D" gate

The significance of High-K dielectrics is that they have a higher dielectric constant than traditional silicon dioxide (SiO2) dielectrics. This allows for a thicker gate oxide layer to be used without increasing the gate capacitance, which can improve the transistor's performance and reduce leakage current.

Metal Gate refers to the use of a metal material (such as tungsten or tantalum) for the gate electrode, instead of the traditional polysilicon material. This is significant because metal gates can provide better control over the transistor's threshold voltage, which can improve its performance and reduce variability.

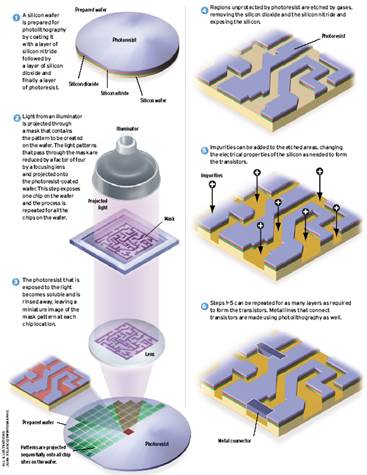

Lithography

- Photo-resist coating

- Illumination

- Exposure

- Etching

- Impurities Doping

- Metal connection

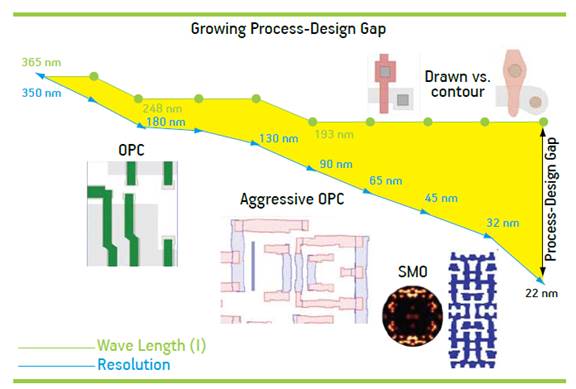

Process-Design Gap

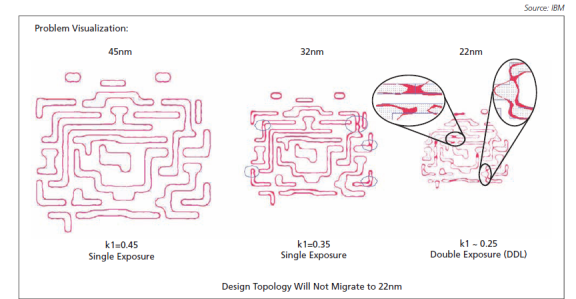

Problem Visualization

One of the main impacts of lithography is that it can cause variations in the dimensions and shapes of the IC's features, which can negatively impact the performance and yield of the IC. This is because lithography is a complex process that involves the use of light to transfer a pattern from a mask to a wafer. Variations in the intensity, wavelength, and angle of the light can cause deviations in the dimensions and shapes of the features, which can lead to process-induced variation.

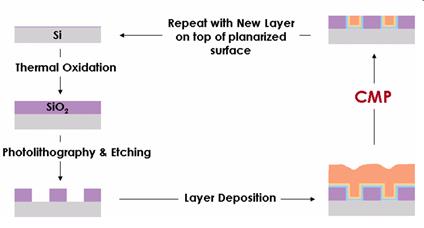

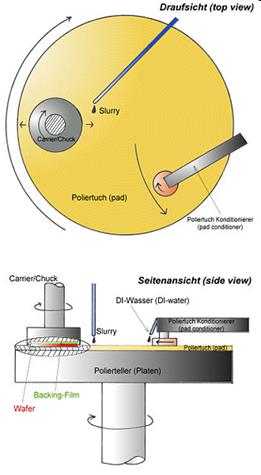

Chemical Mechanical Polishing

Chemical Mechanical Polishing (CMP) is a process used in semiconductor manufacturing to planarize the surface of a wafer. CMP is one of the steps involved in the fabrication of integrated circuits, specifically in the metal connection stage.

Chemical Mechanical Polishing

In terms of bridging the Process-Design Gap, CMP can help address the issue of process-induced variation by improving the uniformity of the wafer surface. This is important because process-induced variation can cause deviations in the dimensions and electrical properties of the transistors, which can negatively impact the performance and yield of the IC.

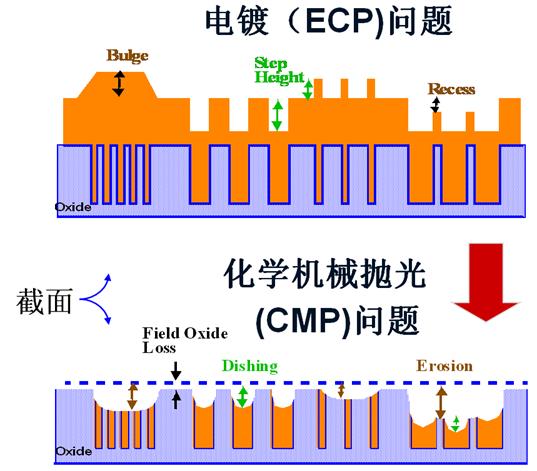

ECP & CMP

By using CMP to planarize the wafer surface, designers can reduce the variability in the thickness of the metal layers, which can improve the accuracy and consistency of the IC's electrical properties. This, in turn, can help bridge the Process-Design Gap by ensuring that the ICs are manufactured according to the intended design specifications.

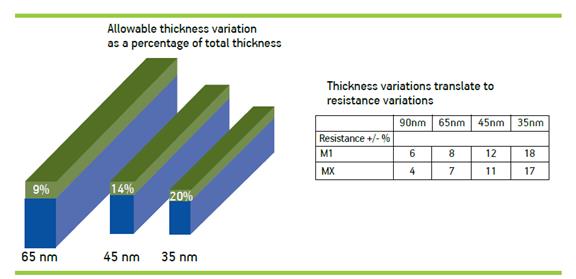

Process Variation

Total Thickness Variation Per Node

"Slippery Fish" at 45nm

- Process variation, impacting yield and performance

- More restricted design rules (RDRs)

- +3 or more rules at 45nm

- +100 or more rules at 32nm

- +250 or more rules at 22nm

- More rules implies larger die size, lower performance

- 10nm is not sci-fiction due to FinFET technology

count: false class: nord-light, middle, center

DFM

What is DFM?

- Design for 💰?

- Design for Manufacturing

- Design for Manufacturability

- Refer to a group of challenges less than 130nm

- The engineering practice of designing integrated circuits (ICs) to optimize their manufacturing ease and production cost given performance, power and reliability requirements

- A set of techniques to modify the design of ICs to improve their functional yield, parametric yield or their reliability

Why is it important?

- Achieving high-yielding designs in the state-of-the-art VLSI technology is extremely challenging due to the miniaturization and complexity of leading-edge products

- The manufacturing process becomes more sensitive to variations and defects, which can degrade the quality and functionality of the chips

- DFM can help to address various manufacturing issues, such as lithography hotspots, CMP dishing and erosion, antenna effects, electromigration, stress effects, layout-dependent effects and more

How is it applied?

- DFM can be applied to various aspects of IC design, such as circuit design, logic design, layout design, verification and testing

- Each aspect has its own specific DFM guidelines and best practices that designers should follow to ensure manufacturability

- For example, some general DFM guidelines for layout design are:

- Use regular and uniform layout structures

- Avoid narrow or long metal wires

- Avoid acute angles or jogs in wires

- Avoid isolated or floating features

- Use dummy fill to improve planarity and density uniformity

- Use recommended design rules and constraints from foundries

What are the benefits?

- By applying DFM techniques in the physical design stage of IC

development, designers can:

- Reduce the number of design iterations

- Improve the collaboration with foundries

- Enhance the product performance and functionality

- Achieve faster time to market and lower production costs

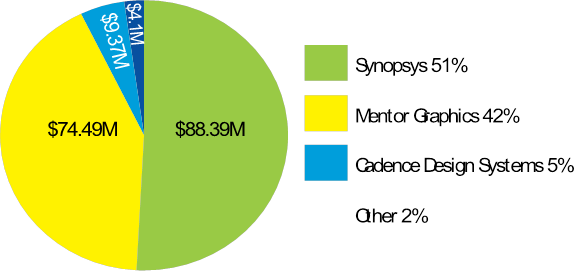

💹 DFM Market Share 2008

💹 DFM Forecast 2009 in $M

Increasing Importance of DFM

DFM Analysis and Verification

- Critical area analysis

- CMP modeling

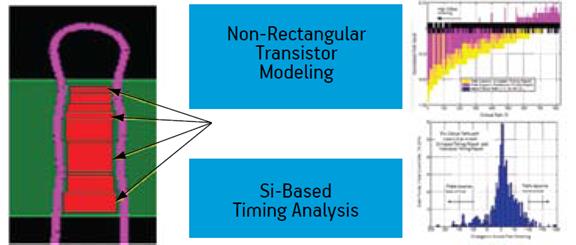

- Statistical timing analysis

- Pattern matching

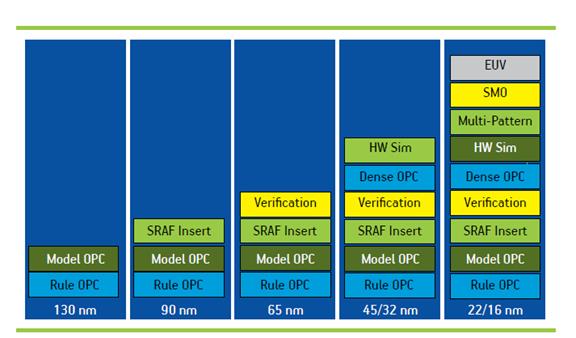

- Lithography simulation

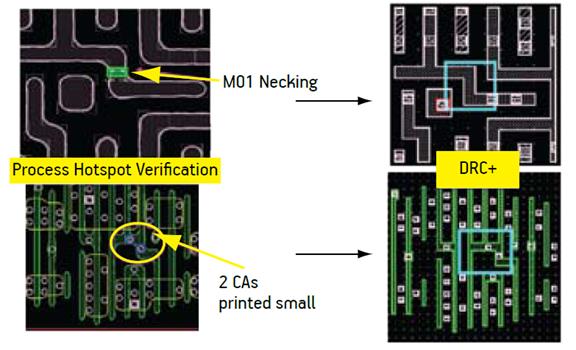

- Lithographic hotspot verification

2D Pattern Matching in DRC+

Contour Based Extraction

DFM Enhancement and Optimization

- Wire spreading

- Dummy Filling

- Redundant Via Insertion

- Optical proximity correlation (OPC)

- Phase Shift Masking (PSM)

- Double/Triple/Multiple Patterning

- Statistical timing and power optimization

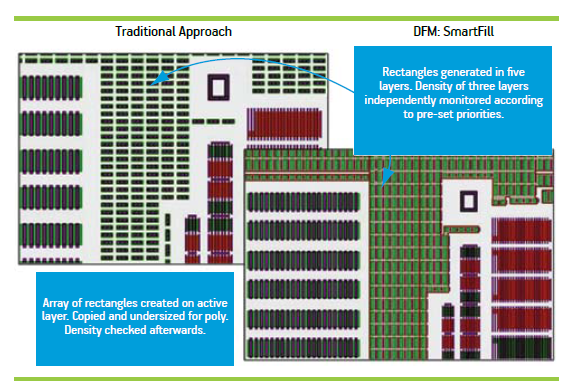

Dummy Filling

"Smart" Filling

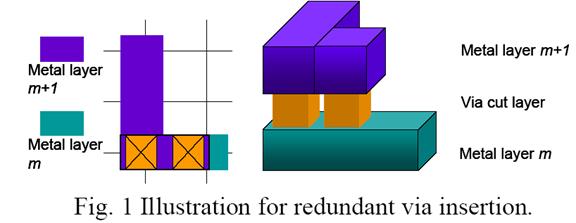

Redundant Via Insertion

- Also known as double via insertion.

- Post-routing RVI (many EDA tools already have this feature)

- Considering RVI during routing

- Looks good, right?

- But actually only few people are using this!

- Why?

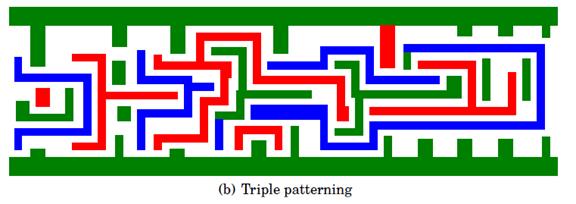

Multiple Patterning (MPL)

- Instead of exposing the photoresist layer once under one mask, MPL exposes it twice by splitting the mask into "k" parts, each with features less dense.

What are the challenges of DFM?

- DFM is not a fixed set of rules, but rather a flexible and evolving methodology that depends on the product requirements, the manufacturing technology and the industry standards

- DFM can also be combined with other design methodologies, such as DFT, DFR, DFLP and DFS, to create a holistic approach to product development

- DFM requires strong capabilities in research, supply chain, talent, IP protection and government policies

Course Structure

- Describe the DFM problems that arise from.

- Abstract the problems in mathematical forms

- Describe the algorithms that solve the problems

- Discuss the alternative algorithms and possible improvement.

- Discuss if the algorithms can be applied to other area.

- Only describe the key idea in lectures. Details are left for paper reading if necessary.

🙈 Not covered

- Algorithms for 3D problems

- Packaging

- Machine Learning/AI Based algorithm